Precision Turned Components Manufacturers in India

Precision turned components are high-accuracy mechanical parts manufactured through a specialized process called turning. This process involves removing material from a rotating workpiece using advanced CNC machinery to achieve precise shapes, tight tolerances, and smooth surface finishes. These components are integral to critical industries such as aerospace, automotive, medical, electronics, and industrial manufacturing.

At Ganesh Precision, we are recognized as one of the most reliable precision turned components manufacturers in India. With operations across Mumbai, Pune, Nashik, and Jamnagar, we have been delivering precision solutions for over three decades, serving the needs of OEMs, small-scale manufacturers, and large-scale factories.

Key Features and Benefits

Applications

Aerospace

Precision turned components are vital in aircraft engines, landing gear, and flight systems where accuracy and safety are non-negotiable.

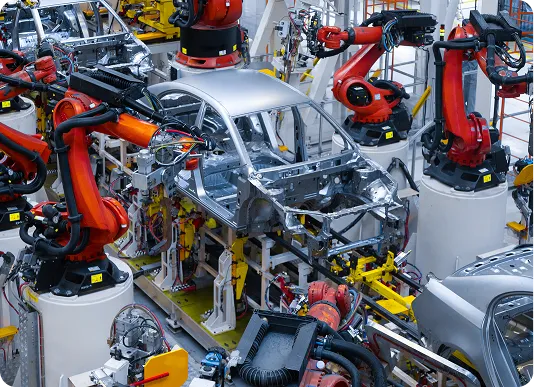

Automotive

We supply precision parts for fuel systems, suspension, steering mechanisms, and CNC auto components, supporting India’s growing automotive ecosystem.

Medical Devices

We manufacture critical medical components such as surgical tools, diagnostic devices, and implants that require the highest precision and clean-room quality.

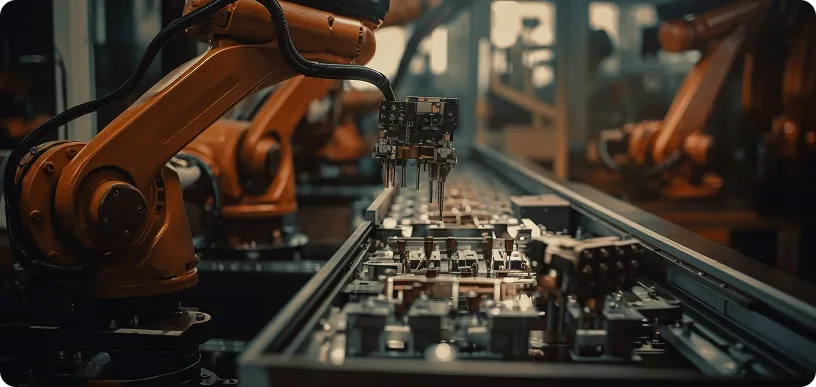

Electronics

Our turned components support a wide range of electronic assemblies including connectors, fasteners, and micro parts—offering reliability in compact designs.

Industrial Machinery

From pumps and motors to heavy-duty valves, we supply rugged parts for various industrial applications and machinery across Indian and international markets.

Why Choose Ganesh Precision?

Precision turned components are high-accuracy mechanical parts manufactured through a specialized process called turning. This process involves removing material from a rotating workpiece using advanced CNC machinery to achieve precise shapes, tight tolerances, and smooth surface finishes. These components are integral to critical industries such as aerospace, automotive, medical, electronics, and industrial manufacturing.

Ganesh Precision, we are recognized as one of the most reliable precision turned components manufacturers in India. With operations across Mumbai, Pune, Nashik, and Jamnagar, we have been delivering precision solutions for over three decades, serving the needs of OEMs, small-scale manufacturers, and large-scale factories.

Ganesh Precision Offers Precision Turned parts

which are used in various sector

Classification

Automobile Sector.

Sensor Industries.

Instrumentation Sector.

Electrical Sector.

Electronic Sector.

Tele Communication Sector.

Moulding Industries.

Valves and Water Industries.

Lighting Systems.

Control Systems.

Central heating Application..

Inspection Facilities:

Vernier Caliper.

Micrometer.

Dial Caliper.

Plug Gauge(GO NOGO).

Ring Gauge(GO NOGO).

Pin Gauge.

Height Gauge.

Raw Material

Free Cutting Brass IS-319 Types I or BS 249 Types I.

Any Special Non Ferrous Material Grade.

Brass as per ROHS Directive.

EN1A-Leaded.

SS – 303.

SS – 304 L.

Threading

ISO Metric (MM Threads).

BA, BSW (INCHES), UNC, UNF, BSP, NPT, BSPT.

Any as per customer specification.

Size

Circumference Diameter 1mm to 200mm with length of any size.

Apart from standard Brass Temperature Sensor parts, we develop customize Brass Temperature Sensor parts as per technical drawing or other relevant data.

Finish

Natural.

Nickle Plated.

Silver Plated.

Tin Plated.

As per customer specification.